Your requirements and applications

You need tools to grind and polish hard to reach surfaces? Your surfaces are so fine that they need to be treated with special sensitivity? We produce all kinds of sizes, shapes and materials. And if there is no matching tool for your individual requirements, our research department will develop it at the highest technological level.

ARTIFEX tools speed up your manufacturing processes and increase the cost effectiveness of your production. Whether primary work like deburring, descaling or deoxidising, or superfine applications like satin finishing, high-gloss polishing and superfinishing – our products are as flexible in application as your requirements are individual.

Your applications at a glance

- Preliminary work

- Deburring and dressing

- Rust removal and descaling

- Removal of lacquers

- Deoxidising

- Cleaning

- Precision work

- Fine and ultra-fine grinding

- Matt finishing, satin finishing

- High-gloss polishing

- Superfinishing

- Processes

- Cylindrical grinding

- Internal cylindrical grinding

- Surface grinding

- Profile grinding

- CNC machining centres

- Robot machining

- Automated polishing in mold making | CNC

In order to transform a manual polishing process for mold making into an automated process inside of a CNC machining center, one needs two things. The matching spindles and the perfect tools.

Specially designed radial or axial deflectable spindles are made by companies like son-x, SN-Spindeltechnik or Biax.Process descriptions: Removal of tooling marks | Polishing track wise with a mounted point... read more

- Automated polishing in mold making | robots

In order to transform a manual polishing process for mold making into an automated process with a robot, one needs two things. The matching spindles and the perfect tools.

Specially designed radial or axial deflectable spindles are made by companies like son-x, SN-Spindeltechnik or Biax.Process descriptions: Polishing of vertical areas with radially deflective spindle and elastic bonded mounted points | Polishing of radius with axially deflective spindle and elastic bonded mounted points... read more

- Cutting edge preparation K-Land

In cooperation with Rothenaicher Schleifwerkzeuge, we achieved a breakthrough combining super-abrasive tool with unique grinding and polishing capabilities. The two recently developed grinding wheel bondings now enable a highly process-reliable grinding of main cutting edge corrections such as K-Land, as well as the increasingly important step correction for drills.... read more

- Ultrafine surface finishing

Ultrafine surface finishing with target Ra roughness values of less than < 0.04 µm with our Series ARTIFEX MFP

In cooperation with the company InduGrind GmbH from Bochum, we managed to achieve the roughness of < 0.04 µm required by the customer and thus the desired surface quality... Application report - Polishing on hard metal

We have developed a new rubber bonding system that is able to hold diamonds perfectly inside the rubber. These new tools allow an automation of manual processes for example with a robot or inside a CNC machining center... read more

- Deburring and polishing of medical instruments

Perfectly polished surfaces make sterilization of the instruments a lot easier. Edges and blades without burrs ensure a good performance. read more

Workpieces: Awls | Drills | Milling cutter | Tweezers | scissors |Cannulas | Clamps | Rasps | Hooks | scalpels and a lot more

Machines: Bench grinders | CnC Machining centers | Robots

- Polishing of circular saw blades and knives

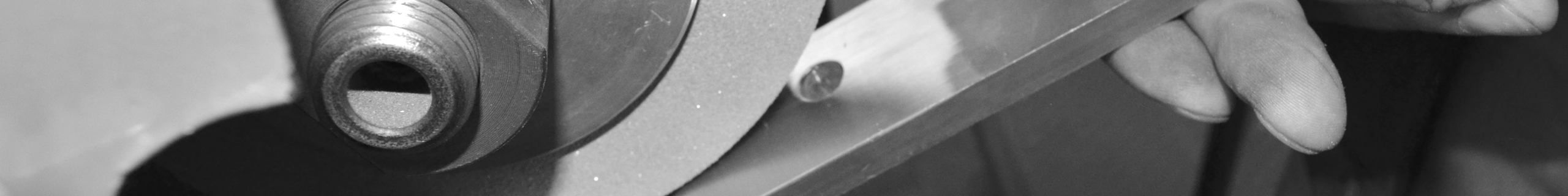

ARTIFEX elastic bonded wheels enable the polishing process to reach the root of the blade, where grinding belts normally do not work.

Turbine blades i.e. for jet engines are polished at the edges either by hand or with robots... read more - Edge rounding and polishing

With ARTIFEX SC-HDR you can reduce micro-defects and processing costs. read more

Process: Edge rounding and polishing of metal drills and cutters (drillpolish)

Workpiece: Cutters and drills

Material: Hard metal

- Polishing of turbine blades

ARTIFEX elastic bonded wheels enable the polishing process to reach the root of the blade, where grinding belts normally do not work. Turbine blades i.e. for jet engines are polished at the edges either by hand or with robots... read more

- Superfinishing in external grinding

Machine: CNC-machines

Workpiece: Machine shafts

Material: Steel as ST52-3, 1.0569With ARTIFEX EK 800 MFP you can achieve a surface roughness of < 0.30 µm. read more

- Superfinishing in flat and profile grinding

Workpieces: Flat steel, Blocks, Plates, Runners, Tracks

Material: For example: 100Cr6 (HRC 60), 17MnCr6 (HRC 63), 42CrMo4

With ARTIFEX EK 600 MFP you can achieve a surface roughness of Rz < 1 µm. read more

- Superfinishing of gears

Process: Profile grinding with path adjustment

Machines: CNC gear grinding machines

Material: For example 20MnCr5Feature:

- Complete process in one clamping of the workpiece

- Low risk of grinding burns

- No geometric changes

- Cutting off the peaks of the roughness profile

- No further process or machinery necessary

With ARTIFEX EK 800 MFP you can achieve a surface roughness of Rz < 1.00 µm. read more

- Polishing of jewellery

Deburring | Satin finishing | Matt finishing | Polishing | Fine polishing

Delivery form:

- Fingerring cones

- Mounted Points

- Peripheral wheels

- Blocks

- Plates…

You can get detailed information in our download area. You have not found your application here? Please contact us!

We provide technologically mature and custom-fit solutions that meet your requirements. We will gladly advise you at your premises. Our team of experts will then develop tools at our research department that are perfectly adapted to your individual requirements.